3D scanning turntable, but also pay attention to the use of methods.

The function and size of the motor determines the working principle of 3D scanning turntable structure and specification..3d scanning turntable, first by the controller issued instruction electric turntable motor starter, followed by electric wheel motor drives the motor core, and coreless motors driven rotary gear wheel to form a rotating tray, the pallet to drive the turntable of 3D scanning operation.

Seemingly simple, use convenient 3D scanning turntable, in fact, has a more complex internal structure. For need for body scanning function will be compared to other 3D scanning turntable simplified, but its accuracy is improved to ensure that building a 3D model of the scanning precision.

Because have limited of the turntable bearing . If increasing the weight the relative accuracy will be decreased, So for human body scanning or large building model constructed by scanning electric turntable, It’s internal structure will more complex than the general 3D scanning turntable , the turret, the load, the rotating stability and accuracy have improved.

3D scanning electric turntable use in 3D printing companies, animation production team, advertising design company, because it can make 3D scan build model more convenient, also can become more efficient of 3D scanning speed.

A lot of people wiill misunderstanding and have a wrong thinking that accuracy is higher, the results is better when selecting a 3D scan turntable, too focus on accuracy problems and worry the quality will be influence by accuracy of scanning.

In fact that’s wrong thinking, because the 3D scanning software has the function of error correction by itself , It’s not high for build scanning and 3D model for general product requirements of precision . Just make sure to improve disk daily correct reasonable use and regular maintenance work.

Most of the time people only focus on the external maintenance of turntable , often ignored the electric machine and wheel inspection and maintenance of the internal gear. Turntable working long time, will be loss of movement and gear, its service life and precision will be decreased.

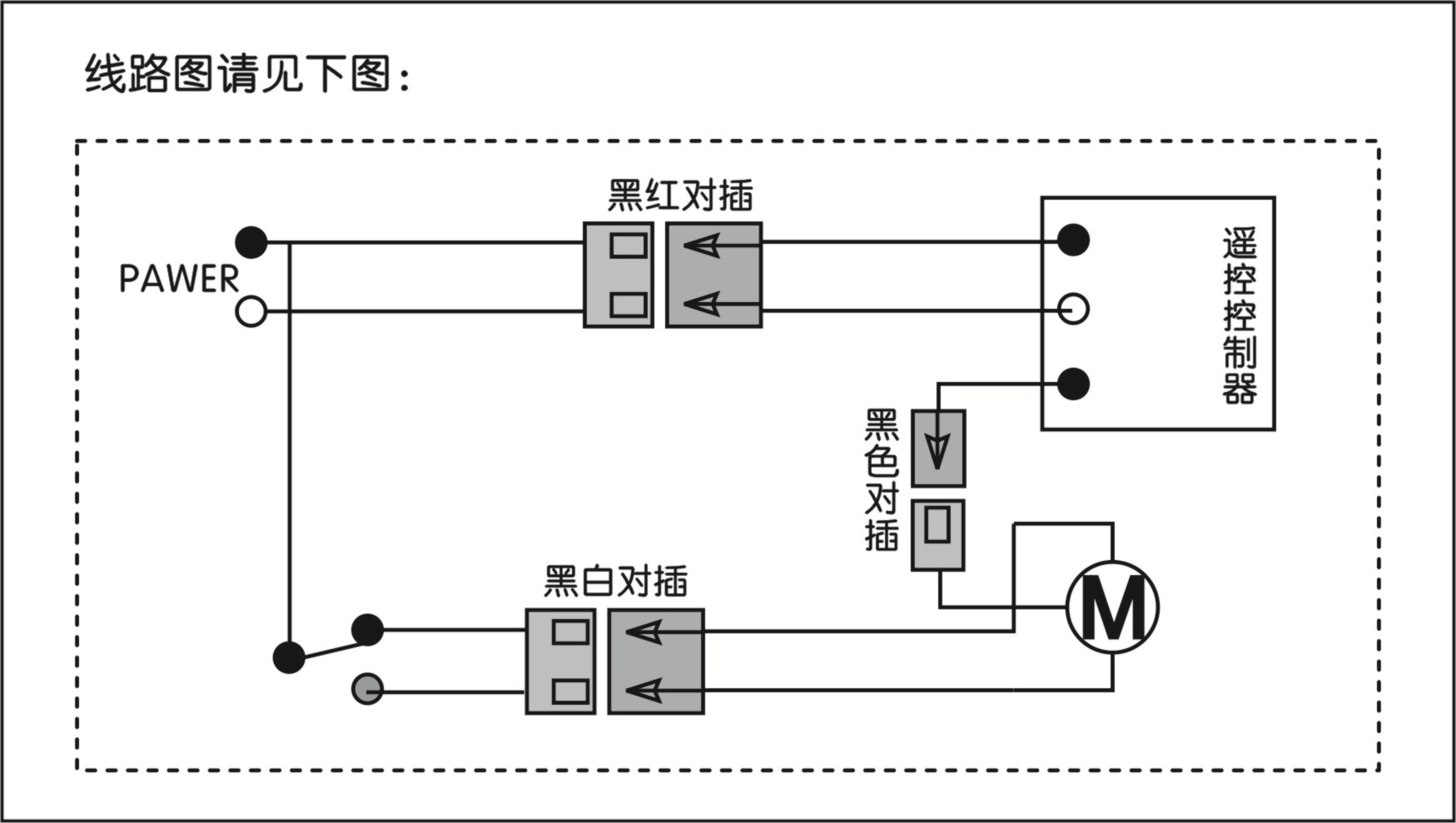

So we need to regularly check the, mechanical failure is found, First check the battery of the remote control, such as lack of power, please replace the battery in time. And again is to check whether the power cord inside the plug, Check the plug is loose or tighten , and make sure the power cord whether damage, aging, If have please replace the power cord immediately.

Make a List of the problem, please open the back cover of the turntable , detection of remote switch control panel is working.

1、Turn on the remote control, check whether the remote control panel is working, is there have any peculiar sound?and test the output circuit make sure have electric out, such as remote control panel does not work, please replace the remote control.

2、Remove the motor independent testing rotation is normal, if you don't work, please replace the motor.

All inspection and maintenance should be performed by qualified technical personnel. Such as need some accessories please contact BKL company. please don’t to replace the same model to other parts, If do that will easy to produce mechanical fault or short circuit.